Bending Dies For Sheet Metal - Remove or slide the four dies along the clamping bar to form angles, channels,. These bottom dies are for standard straight. Shape sheet metal using your bench vise as a sturdy base. The meticulous design of dies and tooling is an indispensable factor in achieving accurate and efficient sheet bending. Specialists in cold forming of sheet metal, we offer a wide range of services, from deep drawing to blanking and bending. Whether you’re bending sheet metal, fabricating intricate parts, or working with tubes and pipes, choosing the right die is. Hemming dies, gooseneck die punches for channel making, and offset bending die sets.

These bottom dies are for standard straight. The meticulous design of dies and tooling is an indispensable factor in achieving accurate and efficient sheet bending. Hemming dies, gooseneck die punches for channel making, and offset bending die sets. Shape sheet metal using your bench vise as a sturdy base. Specialists in cold forming of sheet metal, we offer a wide range of services, from deep drawing to blanking and bending. Remove or slide the four dies along the clamping bar to form angles, channels,. Whether you’re bending sheet metal, fabricating intricate parts, or working with tubes and pipes, choosing the right die is.

These bottom dies are for standard straight. Shape sheet metal using your bench vise as a sturdy base. The meticulous design of dies and tooling is an indispensable factor in achieving accurate and efficient sheet bending. Specialists in cold forming of sheet metal, we offer a wide range of services, from deep drawing to blanking and bending. Hemming dies, gooseneck die punches for channel making, and offset bending die sets. Remove or slide the four dies along the clamping bar to form angles, channels,. Whether you’re bending sheet metal, fabricating intricate parts, or working with tubes and pipes, choosing the right die is.

DIY Metal Bending/Forming/Stamping Die Set For 20 Ton Press YouTube

These bottom dies are for standard straight. Specialists in cold forming of sheet metal, we offer a wide range of services, from deep drawing to blanking and bending. Whether you’re bending sheet metal, fabricating intricate parts, or working with tubes and pipes, choosing the right die is. The meticulous design of dies and tooling is an indispensable factor in achieving.

Sheet Metal Bending Tool and Equipment Isolated on a White Background

Hemming dies, gooseneck die punches for channel making, and offset bending die sets. Whether you’re bending sheet metal, fabricating intricate parts, or working with tubes and pipes, choosing the right die is. Shape sheet metal using your bench vise as a sturdy base. Remove or slide the four dies along the clamping bar to form angles, channels,. These bottom dies.

Bending of sheet metal is a common and vital process in manufacturing

Hemming dies, gooseneck die punches for channel making, and offset bending die sets. Specialists in cold forming of sheet metal, we offer a wide range of services, from deep drawing to blanking and bending. The meticulous design of dies and tooling is an indispensable factor in achieving accurate and efficient sheet bending. Shape sheet metal using your bench vise as.

HCHCR Sheet Metal Bending Die at Rs 35000/unit Sheet Metal Punching

Remove or slide the four dies along the clamping bar to form angles, channels,. These bottom dies are for standard straight. The meticulous design of dies and tooling is an indispensable factor in achieving accurate and efficient sheet bending. Whether you’re bending sheet metal, fabricating intricate parts, or working with tubes and pipes, choosing the right die is. Shape sheet.

Sheet Metal Bending Tool and Equipment Isolated on a White Background

Remove or slide the four dies along the clamping bar to form angles, channels,. Whether you’re bending sheet metal, fabricating intricate parts, or working with tubes and pipes, choosing the right die is. Shape sheet metal using your bench vise as a sturdy base. The meticulous design of dies and tooling is an indispensable factor in achieving accurate and efficient.

punch and die configurations Metal Bending Tools, Metal Working Tools

The meticulous design of dies and tooling is an indispensable factor in achieving accurate and efficient sheet bending. Specialists in cold forming of sheet metal, we offer a wide range of services, from deep drawing to blanking and bending. Whether you’re bending sheet metal, fabricating intricate parts, or working with tubes and pipes, choosing the right die is. Hemming dies,.

Sheet Metal Bending Dies at ₹ 7000/piece बैंडिंग डाई in Ahmedabad

These bottom dies are for standard straight. The meticulous design of dies and tooling is an indispensable factor in achieving accurate and efficient sheet bending. Hemming dies, gooseneck die punches for channel making, and offset bending die sets. Remove or slide the four dies along the clamping bar to form angles, channels,. Shape sheet metal using your bench vise as.

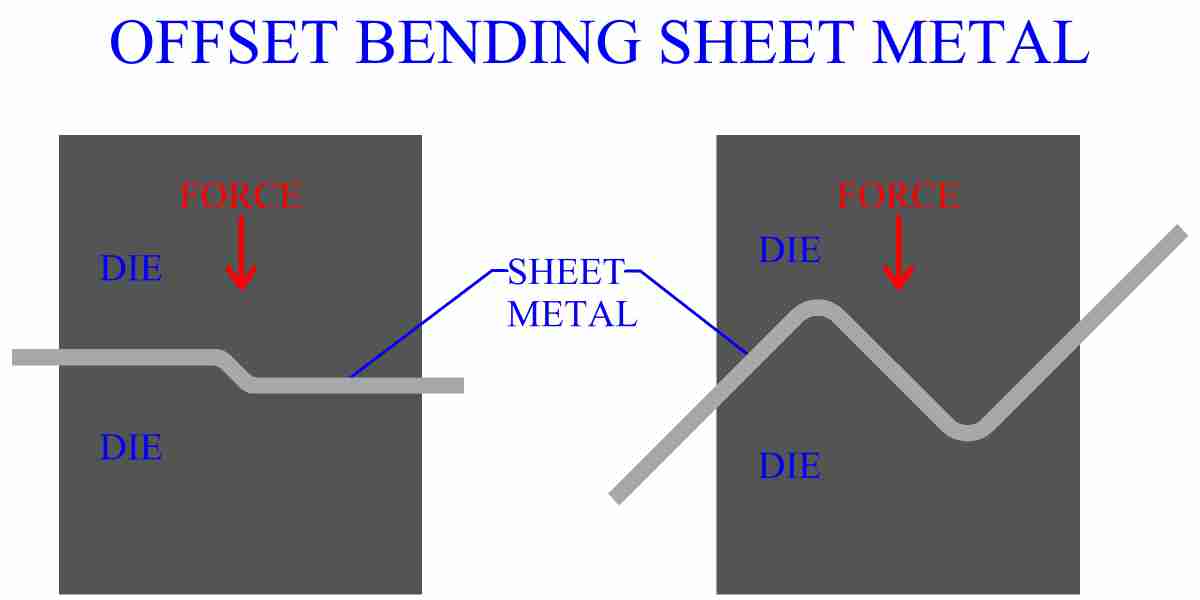

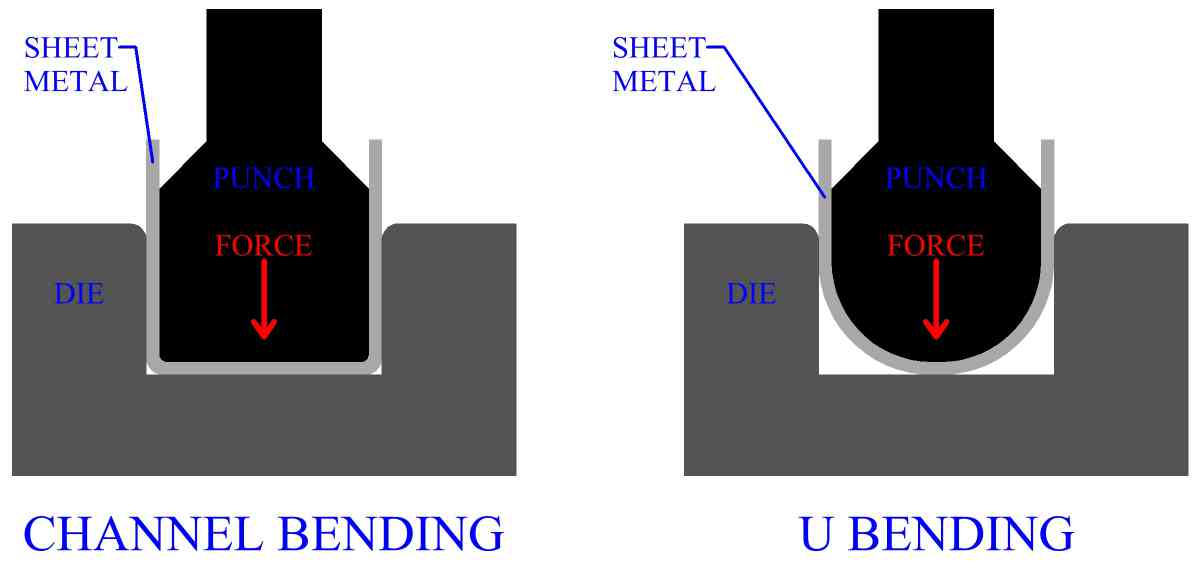

Sheet Metal Bending

Remove or slide the four dies along the clamping bar to form angles, channels,. These bottom dies are for standard straight. Hemming dies, gooseneck die punches for channel making, and offset bending die sets. Specialists in cold forming of sheet metal, we offer a wide range of services, from deep drawing to blanking and bending. Shape sheet metal using your.

Sheet Metal Bending

Remove or slide the four dies along the clamping bar to form angles, channels,. Specialists in cold forming of sheet metal, we offer a wide range of services, from deep drawing to blanking and bending. Whether you’re bending sheet metal, fabricating intricate parts, or working with tubes and pipes, choosing the right die is. These bottom dies are for standard.

Bending Sheet Metal on a Hydraulic Machine at the Factory. Bend Tools

Remove or slide the four dies along the clamping bar to form angles, channels,. Shape sheet metal using your bench vise as a sturdy base. Hemming dies, gooseneck die punches for channel making, and offset bending die sets. Whether you’re bending sheet metal, fabricating intricate parts, or working with tubes and pipes, choosing the right die is. The meticulous design.

The Meticulous Design Of Dies And Tooling Is An Indispensable Factor In Achieving Accurate And Efficient Sheet Bending.

These bottom dies are for standard straight. Hemming dies, gooseneck die punches for channel making, and offset bending die sets. Whether you’re bending sheet metal, fabricating intricate parts, or working with tubes and pipes, choosing the right die is. Remove or slide the four dies along the clamping bar to form angles, channels,.

Shape Sheet Metal Using Your Bench Vise As A Sturdy Base.

Specialists in cold forming of sheet metal, we offer a wide range of services, from deep drawing to blanking and bending.